Have you ever experienced one of those days when you are doing a job you have successfully done a hundred times and one that you could teach your pet hamster to perform……and then it all goes wrong?

May first, 2017 was one such day. It would have been appropriate if it had been the first day of the previous month, but that’s life. The weather was being kind so I decided to treat RGB 43G to an overdue service especially since, earlier in the year at Stoneleigh Spares Day, I had purchased some special oil from Classic Oils that I was keen to try out. It is their finest classic 20W/50 motor oil with added zinc to further reduce wear in the engine. Their discounted price was on a par with the local retailers of the standard stuff. Armed with a few litres plus various filters, points, plugs…and Classic Oils antifreeze, I set about servicing the Jag.

All appeared to go well until I started the engine and much of my prized new oil evacuated itself from the sump via the oil filter. Yup, I had creased the “O” ring seal as I screwed the filter canister back into the filter head. Deep joy. As luck would have it, most landed in my clean oil tray below the car and was therefore retrievable. I managed to remove the canister and change the seal for a spare. By now, I was soaked in oil but I managed to sake the Jag’s thirst with around 12 imperial pints of this vital lubricant.

All appeared to go well until I started the engine and much of my prized new oil evacuated itself from the sump via the oil filter. Yup, I had creased the “O” ring seal as I screwed the filter canister back into the filter head. Deep joy. As luck would have it, most landed in my clean oil tray below the car and was therefore retrievable. I managed to remove the canister and change the seal for a spare. By now, I was soaked in oil but I managed to sake the Jag’s thirst with around 12 imperial pints of this vital lubricant.

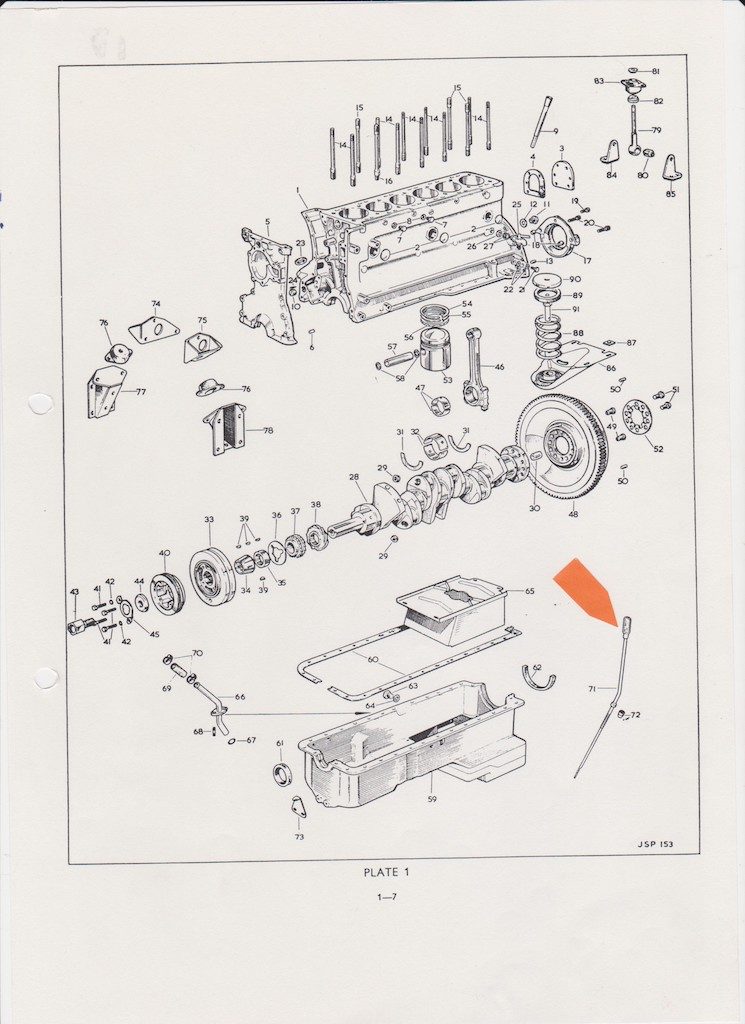

Next act, check the oil level. A quick flick of the handle and the dipstick was withdrawn from its locating “hook” and out of the adaptor tube – well, some of it was. The handle and about two inches of chrome plated stick emerged into daylight but the majority of part number C.22910/1 remained firmly ensconced in the tube and sump. Oh dear! Fortunately, the 420 was still safely drivable and together we were able to attend most of the year’s shows.

But what about that dipstick? The item is made up of two “rods” joined by a spring about a third of the way down from the top of the handle. The steel pin joining the top handle part with the bottom part had sheared leaving both the spring and bottom section inside the adapter tube and sump. Probably caused by metal fatigue……. after only 49 years’ use.

But what about that dipstick? The item is made up of two “rods” joined by a spring about a third of the way down from the top of the handle. The steel pin joining the top handle part with the bottom part had sheared leaving both the spring and bottom section inside the adapter tube and sump. Probably caused by metal fatigue……. after only 49 years’ use.

The first action was to find a replacement. At this point, you realise that the world is not awash with Jaguar 420 dipsticks. I rang Ken Jenkins only to find that he had recently sold his only spare to a member who had suffered the same fate. It was Pat Callis, as ever, who came to the rescue. I first met Pat at a Spares Day several years ago and am always amazed at the treasure trove of hard to find parts for ’60s Jags that he maintains. Once the replacement arrived, it was time to remove what was left of the existing item. How hard could it be? As it turned out, it would have been easier to teach Diane Abbott to count and vote Tory at the next election.

The first idea came from the main club who helpfully suggested that the sump be removed so that it could be withdrawn from below. What, and lose all that precious oil again, not to mention dropping the front suspension assembly. There has to be an easier way involving a lot less spannering and oily bits. One wag did suggest turning the car upside down and letting gravity do the work. Hmmmm.

The first idea came from the main club who helpfully suggested that the sump be removed so that it could be withdrawn from below. What, and lose all that precious oil again, not to mention dropping the front suspension assembly. There has to be an easier way involving a lot less spannering and oily bits. One wag did suggest turning the car upside down and letting gravity do the work. Hmmmm.

The first sensible and most popular idea was to employ a small but powerful magnet to drop down the adapter tube and haul out the remains of the stick. It didn’t work. How about unscrewing the said tube from the engine casting? This would involve removing the rear exhaust manifold and pipe to gain space to use some form of gripping tool. Also the tube is pressed into the block on this model not screwed. My garage said that by tapping it with a hammer it would eventually loosen, but try swinging a hammer down there. I had even bought a spare tube – the last one on the planet – just in case I damaged the old one in the process. Another one bites the dust.

Not to be beaten, a length of stainless steel wire was procured with the intention of slipping it between the stick and the side of the tube and lifting the stick by friction. No chance, it wouldn’t fit down. Still on a roll, it was decided to hammer it flat and put a slight curve on it to help lift the stick. This we did, but the recalcitrant part remained stubbornly in place whilst the flat wire glided quietly passed, no doubt helped by that slippery classic oil.

Finally, with all options exhausted, Bob King, who happened to be passing and decided to join in with the fun, suggested the use of a fret saw blade. A very small fret saw blade with its locating pin cut off at one end. The theory behind this is that once inserted between the spring at the top of the stick and the wall of the adapter tube and then slightly twisted so that the teeth faced inwards, there would be enough purchase on the spring to allow the teeth to engage with the spring coils and so enable the stick to be withdrawn. An ecstasy of fumbling later and I hadn’t yet succeeded. It was whilst I was, dejectedly, packing up that Bob requested a thin flat-bladed screw driver. Why, I asked. Because, said Bob, I need it to stick through the spring coils emerging from the tube. Give it one last go. Once secured, we were able to pull it free from the black abyss below and insert its replacement.

Finally, with all options exhausted, Bob King, who happened to be passing and decided to join in with the fun, suggested the use of a fret saw blade. A very small fret saw blade with its locating pin cut off at one end. The theory behind this is that once inserted between the spring at the top of the stick and the wall of the adapter tube and then slightly twisted so that the teeth faced inwards, there would be enough purchase on the spring to allow the teeth to engage with the spring coils and so enable the stick to be withdrawn. An ecstasy of fumbling later and I hadn’t yet succeeded. It was whilst I was, dejectedly, packing up that Bob requested a thin flat-bladed screw driver. Why, I asked. Because, said Bob, I need it to stick through the spring coils emerging from the tube. Give it one last go. Once secured, we were able to pull it free from the black abyss below and insert its replacement.

Job done and Bob even repaired the old one. Hopefully, I will not need a spare, but I will keep that saw blade just in case. See the accompanying photo re-enactment. Thanks to Bob and everyone else who contributed to the resolution.

Job done and Bob even repaired the old one. Hopefully, I will not need a spare, but I will keep that saw blade just in case. See the accompanying photo re-enactment. Thanks to Bob and everyone else who contributed to the resolution.

Neil Shanley