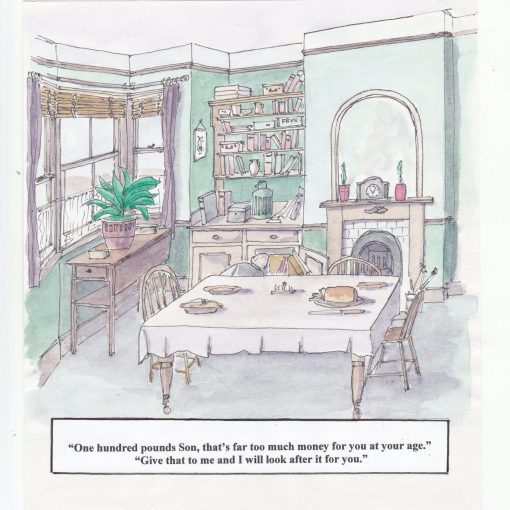

My mechanical adventures from boyhood, when I was barely able to lift a spanner, to now when I can just about wield one.

Let me start at the beginning of my mechanical adventures. Like most small boys I have always been interested in making and repairing things. I liked taking things apart, but I didn’t always manage to get them together and working again. You learn by your mistakes and I have made many.

When I was about 12 years old in the 1950s, I made the usual go- cart. Two large pram wheels at the back, two small ones at the front, and steered by a piece of sash cord. Mine was special, though, because it had two seats and a fairing on the front to reduce drag.

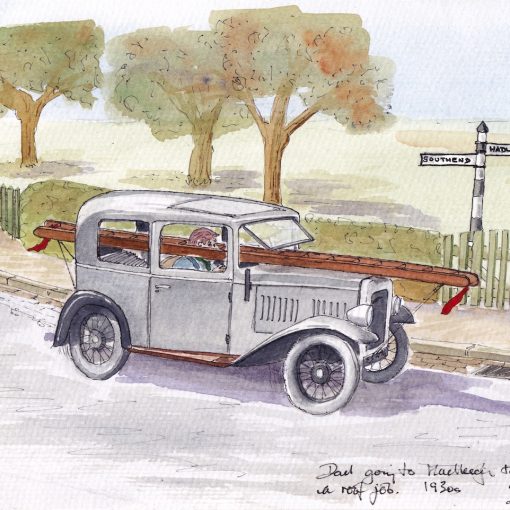

I gave my sister a ride on its trial run. Gaining speed going down our local hill, all was well as we approached the T junction. I intended to turn the 90-degree corner on two wheels, but then disaster struck. The anti-drag fairing fouled the steering bar, so both my sister and I ended up in the middle of the main road. Luckily, the local estate agent passing in his Austin 10 just managed to stop in time, otherwise my sister and I would have been no more.

Moving on to another venture in the early 1960s, I was now 17 and getting more adventurous.

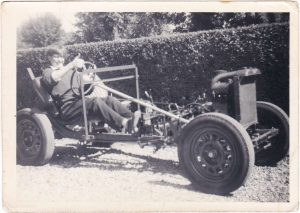

In 1964 I bought an Austin Big Seven for £15. It was a wreck, but I decided to build a sports car body on the chassis and get it roadworthy.

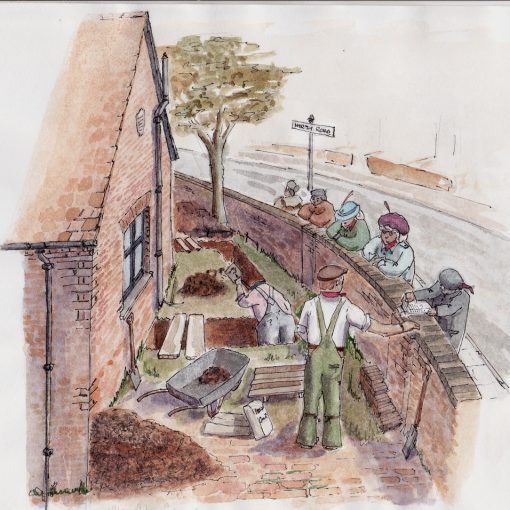

In the early stages, Mr Hill of 21 Barking Road kindly let me work on it in his front garden.

I remember hacking off the old body with an axe to expose the chassis. I decided to fabricate a frame for the body by drilling, cutting and bolting the angle irons from an old bedstead to the chassis. Another mistake; bedstead irons are very hard. An electric drill was far too expensive on my wages of £3-5-0d per week; I only had a small breast drill and hundreds of blunt 1/4-inch bits.

However, I managed it and then bolted timber battens to the iron and screwed four 8ft x 4ft sheets of aluminium to the battens with round-head brass screws; I had the body completed.

I got an old steering wheel and column from a BSA sports car which was longer than the original Austin column and allowed me to position the driving seat further back, nearer to the rear of the car.

As regards the engine, cleaning the plugs seemed to be enough to make it go. It was a great day when the Ministry of Transport man came to visit (this was before MOT tests) and told me that I could take it on to the road.

It turned out to be horrible to drive, so I sold it to my cousin for £10 who then sold it on. I never laid eyes on it again. Was this a mistake? Perhaps, but I learned a great deal.

This was followed by motorbikes, a Bond three-wheeler, a Frogeye Sprite, getting married and three children, and driving the firm’s Mini van for thirty-five years before finally obtaining a Jaguar.

I had first been drawn to Jaguar cars when being driven in my Uncle Geoff`s Mk IX and again later, when he owned a Mk X. In 1985 I saw an advert in the Classic Car Magazine for XSC 88, a manual Mk 2 in black with red upholstery, my favourite colour combination. This particular car was being offered by Riverside Classic Automobiles in Bury St Edmunds. My son Paul and I travelled up one Wednesday evening to view the car. After seeing it, kicking the odd tyre and taking a small test drive, I purchased the car for £3,000.

I had first been drawn to Jaguar cars when being driven in my Uncle Geoff`s Mk IX and again later, when he owned a Mk X. In 1985 I saw an advert in the Classic Car Magazine for XSC 88, a manual Mk 2 in black with red upholstery, my favourite colour combination. This particular car was being offered by Riverside Classic Automobiles in Bury St Edmunds. My son Paul and I travelled up one Wednesday evening to view the car. After seeing it, kicking the odd tyre and taking a small test drive, I purchased the car for £3,000.

The following weekend we collected the car to drive it back to Southend. Somewhere near Rochford, as we were nearly home I asked my wife if she would like to drive. She took the wheel and was driving along Manners Way as a bus came towards us. There was not enough room for both vehicles to pass, so Sue started to slow down and brake. Unfortunately, the offside front brake was more efficient than the nearside front brake, with the alarming effect of causing the car to veer right towards the bus and necessitating a rapid correction of the steering.

It was the first and last time that Sue ever drove that car.

I had that car for some years. I enjoyed repairing and driving it to shows, enabling it to be used for friends’ weddings and the annual family holiday and outings. However, in 1988 I saw an advert in the local paper for an automatic MK 2 and it gave me an idea for my next project; convinced that my wife Sue was missing out on all the enjoyment, I started looking for an automatic Mk2 to buy and restore, so that we could both share in experiencing the Jaguar thrill. Luckily, Sue accepted my lame excuse.

In August 1988 I decided to view a Mk 2 automatic available locally. I arranged an inspection and unearthed what is now commonly called a “barn find” (a.k.a. ‘money pit’) in a lock-up garage behind Thorpe Bay Broadway. Stuart Dunn, the owner, wanted £500 for the car; I offered £300, then left my phone number and walked away. Later that evening, Mr Dunn left a message to say that he would accept £300.

What had I done? I now had two Mk 2s, at least until the late 1990s when XSC 88, my first Mk 2, had to be sold on. The car, along with one of its new owners, has featured many times in the Jaguar Enthusiast`s magazine and one day we may meet up at one of the car shows.

It turned out to be a 30-year project to restore UOO 874, with plenty of mistakes along the way:

1988 – Took off the head

1989 – Restored and tested the head

1990 – Removed and restored the front sub frame

1992 – Removed the 3.4-litre engine

1993 – Rebuilt the engine. Mistake number one, storing a rebuilt engine for twenty five years!

1995 – Started on the bodywork.  The sills and door bottoms were all rusted out; every metal body section from the ground to about 12 inches up was cut out and new metal sections were let in, fitted, welded, lead loaded and filled ready for re-spraying. The rear suffered from “Jag sag”, so new rear springs and hangers were fitted.

The sills and door bottoms were all rusted out; every metal body section from the ground to about 12 inches up was cut out and new metal sections were let in, fitted, welded, lead loaded and filled ready for re-spraying. The rear suffered from “Jag sag”, so new rear springs and hangers were fitted.

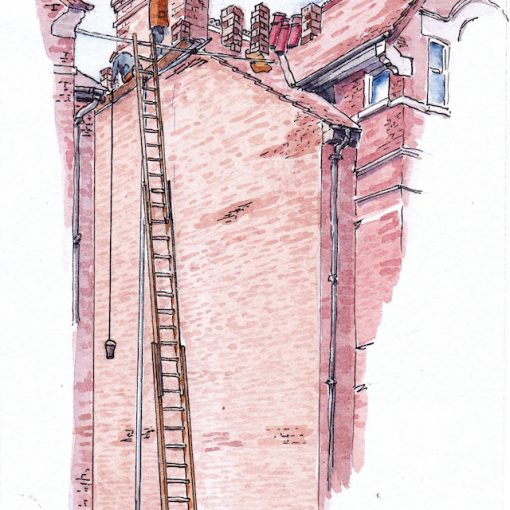

2000’s – I continued with the front sub frame, rebuilding it with new coil springs, dampers, track rod ends, bushes and painted it ready for refitting. Sound secondhand doors and boot lid were purchased and repairs to bottom edges were made. Many hours were spent lead loading the sills to gain fair fit to door shuts. I then removed the existing Webasto sun roof and sourced a secondhand roof section from a breakers yard. Cutting, fitting into the roof section, welding and filling ready for spraying preparations caused lots of fun!

2011 – I sourced and fitted a 5-speed gear box with a new cross member mounting made by my son, Paul. Next was the back axle. This was sent off to Newood Transmissions Ltd for overhaul and then refitted with new brake discs, pads, pipes and cylinders. New torque arms and bushes were also fitted, then all was painted and re-fitted. A new wiring loom was installed in the car and ancillaries were refitted in the engine bay.

2013 – A big day when the restored engine was refitted with help from Paul.

2014 – Another year before the engine was run up in situ.

2015 – Yet another year and the car is getting ready to be transported to the spray shop for painting. The repaired bodywork was temporarily protected with a primer coat; this was then removed, stripping back to bare metal when it was at the paint shop. It was then prepared, filled and finally sprayed with the original Jaguar colour Opalescent Dark Green.

2016 – Now back at my workshop and being fitted out, with new headlamps, side lights etc. The windscreen and back screen were fitted by specialists – do not try fitting these yourselves! My son Paul and I installed a new headlining and sun visors.

2017 – We refitted the repaired and treated leather seats and got the car ready for a first test drive. Doug Warren from the Essex Thameside region came to inspect the car so that we could get the original registration number back. I fitted new number plates and we were insured, taxed and ready to go. As the 5 speed Getrag gearbox had no take-off for a mechanical speedo drive, my son Paul adapted the original speedo head by fitting a digital speedo to the rear of the dial and recalibrated it to match existing ratios.

2018 – First test runs and the start of finding many small items that needed attention. The main one was a vibration on the prop shaft that has now been resolved after many hours adjusting it with two jubilee clips and finally welding a 54gram weight to the shaft.

The car has now been to three car shows and I am very pleased with the end result.

Thank you all who helped and thank you for your patience in reading this.

Colin and Paul Cooper